Prompted by this discussion on the forums, I wanted to share some recent experiments with two-part epoxy.

My situation is this: I'm preparing an army for a special TMP project. This will be a double-size Orc army for Mighty Armies, using two of the boxed army sets formerly available from Mongoose, and normally available from Rebel Minis (but not, as it happens, at this moment - it's temporarily out of stock).

Half of the army consists of the figures previously painted for TMP by the All About Miniatures painting service.

For the other half, I sent a boxed set to Fernando Enterprises in Sri Lanka, and asked them to match them to the figures I already had, using the photos that were online. Unfortunately, this was part of a large order of 15mm fantasy figures, and Fernando Enterprises mistakenly painted the figures to match the box art. I should have caught this when they sent me photos of the painted figures for approval, but my brain was absent that day, and I said "Ooh, pretty!" and approved them.

So now, I'm trying to take two sets of figures, and by adding a few highlights and colors, make them look like they belong in the same army. I'm also basing the figures from Fernando, and rebasing the figures from All About Miniatures (as they lost the original bases, and glued them down to non-standard bases for Mighty Armies).

Also, I know this army is going to eventually be shipped far away, so I wanted to base them in a way that I hoped would be resistant to damage. So I decided to try two-part epoxy, as I understand it is a better adhesive than white glue or superglue.

Two-Part Epoxies

As far as I can tell, the two-part epoxies that you can buy in the store fall into three types: regular, fast, and specialist (for gluing special materials, such as plastic-to-plastic). My first experiments were with a fast-drying epoxy, so-called "Five Minute" because it sets in five minutes.

Two-part epoxy comes in a double-syringe set, designed to automatically dispense equal amounts of both ingredients as you press down on the plunger. (Theoretically equal amounts, but it never seems quite equal...) I use a plastic lid to hold the epoxy, and a wooden craft stick to stir it up. Only by experience can you tell how much epoxy to dispense for your current basing project.

Take a moment to stir the epoxy well, as you can get sticky or unhardened epoxy if you don't. More stirring means more air bubbles, but the bubbles stay "on the inside" so don't seem to affect anything.

I am basing on 3mm-thick plywood bases from Litko - these are their thicker-type wooden bases, which I prefer as it seems to keep players from handling the figures instead of the bases. As a matter of personal preference, I paint the wooden base sides prior to gluing on the figures, then touch the sides up against just prior to flocking.

It takes practice, but I've become fairly good at spreading a coat of epoxy onto the bases that matches the thickness of the cast-on bases on the figures.

(I should explain that the reason for the thick layer of epoxy is to avoid the "pitcher's mound" look by leveling out the tops of the bases.)

I then stick the figures into the epoxy.

I can mount about 30 figures in one batch, before the epoxy starts to set.

Until the epoxy sets, though, I have to watch the figures to make sure they are standing upright as I want them to be.

Epoxy is a very sticky material, so have a paper towel handy to remove any epoxy that sticks to your fingers (unless you want to leave epoxy fingerprints on your minis!).

The epoxy should harden in a few hours, but I generally wait a day before proceeding. Also, I dislike the odor of "fast" epoxy, so I do the basing in an isolated part of my house. (You might prefer a shed or garage, or a room with an open window.)

With practice, I've become fairly proficient at spreading the epoxy all the way to the base edges. The epoxy naturally forms rounded "shoulders" on the edges, but it doesn't seem possible to "slope" the epoxy (it's too sticky and too cohesive).

However, if I've got a missing spot, I've found that spackle works fine for filling in along an edge.

The final steps are then to paint the surface a mud color, let it dry, brush on some white glue, dip the base in flocking material, let dry, and seal with a clear spray coat. The hardened epoxy usually takes two coats of paint to get a solid color.

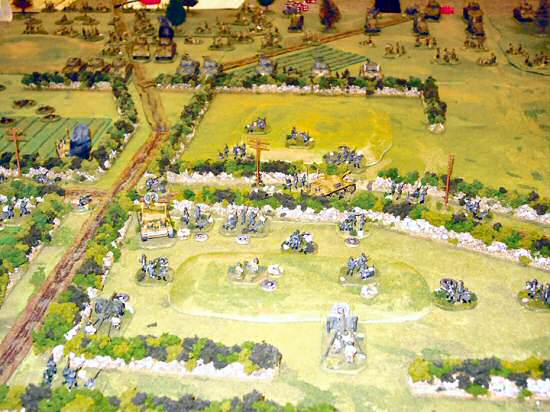

Here are some Goblins (above) which have been flocked, sealed, reflocked to get the spots I missed, and sealed again. Below are some Orcs still on their first flocking:

Regular Epoxy

Subsequently, I've also experimented with "regular" epoxy. The brand I'm using has the advantage of having no smell that I can detect, and it is slightly lower in price. The disadvantage is that it takes longer to set. I find it a good idea to prepare the minis by filing their bottoms smooth beforehand, as otherwise you might have a mini topple over while waiting for the epoxy to set - and then you'll have a mini covered with sticky epoxy on one side!