It's become clear that I'm not going to make my deadline - my wife returns this week! - without making changes. The new dungeon mold has greatly improved my efficiency, but even so, I'm just not producing enough wall-building blocks.

Which is partly my fault. In my original plan for this dungeon, there would be only door openings - but no doorways. Then, in the early stages of production, I saw all these door arch pieces and column pieces stacking up (they were in the mold, but I wasn't using them) - so I thought, why not make doorways?

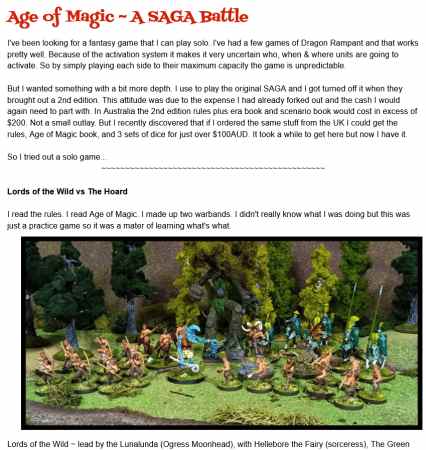

The photo above shows two of my dungeon modules - a room piece with a doorway arch (left) and a corridor piece with an entrance (right).

For the doorway, I'm using the standard arches from the basic dungeon mold (which gives me at least two sizes of doorways), plus some column pieces.

Then I got even fancier, and decided to use some different column pieces (from the same mold, but wasn't using) to make an "entrance" to tie the corridor piece better with the room piece.

Unfortunately, while it's true that I was making use of blocks and bits that I wasn't using for walls or floors, the doorways and entrances did require the occasional half-block (cube) or one-and-a-half blocks. Which happen to be the pieces I'm always running short of for my walls!

So, for the time being, I'm halting all work on doors and entrances. I just want to finish the basic walls and floors!

One Last Experiment

Someone suggested that I try the "ink colorant" experiment again, but this time to try one of the hobby inks instead of India Ink. So I got out my Reaper inks - black and blue - and tried coloring a batch of no-name plaster.

I add the ink to the water (creating a dark, dark liquid), then sprinkle in the plaster dust. To my surprise, this works about the same as the India Ink - the color "breaks up" when the plaster is mixed in. The black ink creates light grey blocks, while the saphire blue ink creates light blue (green?) blocks - too pale to be noticeable.

It's Time for Merlin

I now realize that the only way to make my deadline is to switch - from Plaster of Paris to dental plaster. Specifically, it's time to try Merlin's Magic - a relatively dense dental plaster that has the virtue of setting up in half the time of Plaster of Paris - which theoretically means I could produce twice the amount of blocks in the same amount of time!

Dental plaster costs about double what Plaster of Paris costs, and must be purchased in larger quantities - typically 25- and 50-pound boxes. On the other hand, dental plaster is a much harder material, and comes in a variety of shades (I chose dark grey).

Now I begin casting like a madman, running batches through the molds as fast as humanly possible, tossing them into the food dehydrator to dry, then gluing the dried blocks and tiles together to form floors and walls. One trick I've found is to use half of a CD case as a "rack" to hold (and keep square) a module's worth of floor - which I can place on top of the dehydrator, where the heat helps the glue dry faster. (I also use one of the Hirst Arts' tips and glue the floors upside-down - which theoretically keeps the floor surface level, even if the blocks aren't perfectly scraped.)

I'm fairly pleased with the Merlin's Magic - it's easy to mix, very easy to pour into the molds, has fewer bubbles, and sets up rapidly. The only downside is that my blocks are coming out slightly concave on the bottom - I must somehow be over-scraping...

So, Did I Make It?

Alas, two days of casting blocks like a madman has not quite finished the project... The floors and most walls are complete, but the doorway/entrance pieces exist as floors only. Time to pack it up, and clean the kitchen - my wife is on the way home!!!